Punching systems for manufacturing

Working closely with automotive manufacturers and other industries for almost 3 decades, Stelram has a broad working knowledge of punching systems and their application within the assembly process.

Whether using a pneumatic or hydraulic punching machine, you need to be sure that the equipment is robust and reliable, and designed to punch holes quickly and cleanly through your chosen material. We’ll advise on and supply only the highest quality punching systems, selected in line with your specific manufacturing requirements, based on material, texture, particle content and size.

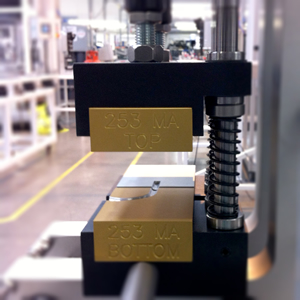

Pneumatic and hydraulic punching machines

Our punch machines can be supplied as standalone units, or our engineers can integrate them into a larger production line system.

We offer both guillotine and press punching systems, fitted with either servo motors, hydraulic or pneumatic rams to punch out the exact shapes you require. In addition to their application in the automotive sector, these machines can also be used for the production of some consumer goods, with the capability to punch consistent and accurate holes in materials such as:

- Plastics

- Carpets

- Aluminium

- Steel

- Other metals

By utilising punching systems, your assembly line can run faster and more efficiently – smaller, high volume detail work like punching can take a long time when done manually, so it makes sense to mechanise the process. Our punching machines can also help you to minimise waste, saving you money as well as increasing output.

Expert advice, ongoing support

Here at Stelram, we believe in providing quality products at competitive prices, and have built a strong reputation for our excellent customer service and after sales care and support.

If you’d like some friendly advice regarding the best type of servo, pneumatic or hydraulic punching machine, or integrated punching system for your needs, please give us a ring on 01924 339111 or send us a message with your questions and we’ll get right back to you.

01924 339111

01924 339111