Robotic automation – solutions for assembly and manufacturing

Robotic automation can offer a variety of solutions to help you at every stage of your assembly line. No matter the size or scope of your project, our engineering specialists will apply their knowledge and experience to ensure that your robotic systems carry out their required functions accurately and efficiently, adding tangible value to your manufacturing activities.

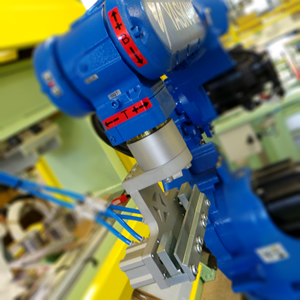

From standalone, single-purpose robotic arms, to complex, integrated robotic assembly systems, we design, manufacture and install robust and reliable technologies for all industries, including automotive manufacturing and food and drink production.

Whatever materials you’re working with, and however detailed the function, we can develop a robotic solution to meet your exact specifications.

The benefits of robotic systems

Robotic systems have been widely adopted in manufacturing over recent decades, due to their reliability and capacity to offer many advantages over manual assembly.

Among the many benefits that robotics represent are:

- Endurance – providing your system is well maintained, it can last many years, resulting in a high level of investment payback

- 24/7 operation – robots don’t need to take breaks, go on holiday, or sleep, so your assembly line can be operational very hour of every day if required

- Flexibility – your system can be programmed for different tasks, and can be adapted and updated by our engineers should your manufacturing requirements change

- Accuracy – robotic systems can perform highly specialised or detailed tasks with consistent results

- Lean manufacturing – implementing a robotic solution will help you to reduce waste and minimise the risk of damage to parts and materials

- Speed – tasks can be performed more efficiently, increasing productivity and helping you to meet client demands

- Reduced overheads – all of the above benefits combine to significantly reduce your manufacturing costs

- Integration – our equipment can be installed to complement existing assembly tooling: one simple enhancement can change the way your entire assembly line works

Robotic automation applications

The functionality provided by robotics really has no limit, but in relation to the manufacturing process, the most common applications include:

Using HMI and PLC, your system can be pre-programmed for ease of use, and guided by our smart, sophisticated vision systems, for controlled and accurate repetitive operation, and seamless activity.

From simple, single-solution robotic arms, to dual arm systems or highly dexterous multiple-axis robots, we promise to deliver exceptional technology on time, on budget and with excellent after-care and ongoing support as standard.

Speak to a robotic engineering expert today

If you’re looking for a versatile and responsive assembly solution, call our engineering experts today on 01924 339111 – we’ll be delighted to discuss your project under no obligation, and offer advice tailored to your individual business needs.

01924 339111

01924 339111