Innovative automation engineering

Stelram has nearly 30 years of experience in automation engineering, designing and developing outstanding solutions to increase assembly line efficiency and quality.

While our primary focus is on the food and drink and automotive sectors, we can adapt and apply our technologies across any manufacturing or production facility, working closely with our clients to ensure that their objectives are met in full, and within budget.

Whether you’re looking for a fully integrated assembly system or require a bespoke automation solution, our talented, highly trained engineers will rise to your production challenges. We’ll deliver reliable and robust technologies to increase capacity, reduce costs and errors, and bring your manufacturing process right up to date.

Automation, automotive and food production technologies

Every production line has its own unique combination of operations, experiences changing demands from end-users, and needs to meet the most recent health and safety regulations. Using current and emerging technologies, we create machinery that performs at every turn.

Our engineering expertise has led to the development of multiple, effective technologies that cover a vast range of manufacturing functions, including:

- Checking – presence, colour, shape and orientation

- Conveying – belt, chain, bands, spiral, roller, vertical and vibrating

- Cutting/Slicing – blades, ultrasonic knifes, water jets and laser

- Depositing and dispensing – fluids, powders and solids

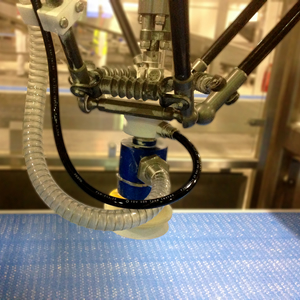

- Handling – grabbers, grippers and suction cups

- Packing – food, components, liquids, Vertical Form Fill Seal (VFFS), bread baggers

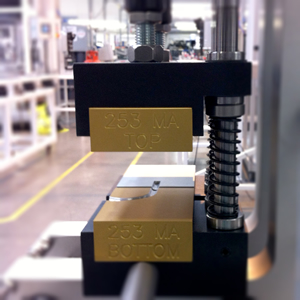

- Punching – hydraulic and pneumatic

- Welding – sonic welding equipment

This list is by no means comprehensive, so if you’re seeking an alternative automation solution, just give us a call on 01924 339111 and we’ll do everything we can to meet your needs.

Key automation technologies

When you’re running a busy assembly line, accuracy and ease of operation is essential – human staff members need total control over their automation counterparts, and you need to have complete confidence in the speed and output quality offered by the machinery you invest in.

Among the leading technologies we adopt to ensure a seamless production process, you’ll find:

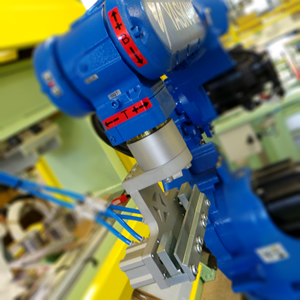

- Robotic systems – the modern solution for repetitive tasks that require complete consistency and accuracy

- Vision systems – these provide precise position, size, orientation and image data for robotic and mechanical operations

- Programmable Logic Computers (PLCs) and Human Machine Interface (HMI) – easily set, control, monitor and manage your automation systems

Engineering advice and support

If you’re looking for the very best in food production technology, automotive assembly systems or a bespoke solution to improve your manufacturing processes, call our automation engineering experts on 01924 339111, or send us a message with a brief outline of your project, and we’ll get right back to you.

Processes We Use

Click on each process below to read more

01924 339111

01924 339111